Always in the loop

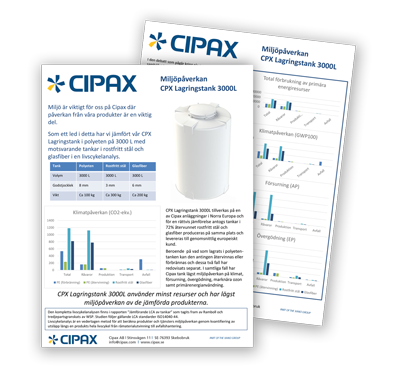

As an actor in the plastic industry, it is our responsibility to ensure that the material remains in the loop and that our impact on the climate is as small as possible. We work with sustainability in all areas and our sustainability work is a natural part of our daily work, both in the short and long term. By actively working with sustainability at all stages, we create long-term growth and increased value for everyone who uses our products, but above all for future generations.

Our sustainability work is based on the Group's sustainability policy. This is based on the UN Global Compact, which comprises ten principles based on the UN Declaration of Human Rights, the ILO Fundamental Conventions on Human Rights at Work, the Rio Declaration and the UN Convention against Corruption.

Our sustainability work focuses on:

- Climate emissions

- Energy use and energy sources

- Material use

- Waste management

- Employer branding

- Quality

- Financial result

Sustainability report

Since 2017, XANO has reported the Group's joint sustainability work in an annual sustainability report. When it was desired to have an overall picture of the sustainability activities in the group, a sustainability policy was developed centrally and implemented in all units. In 2018, the Board adopted a sustainability strategy that describes the overall direction for the continued work. Furthermore, targets were formulated for improvements in selected areas of the environment and personnel. Read more about our sustainability work in XANOs Annual report.