Containers and Tanks

CPX containers and tanks from 10 to 23,000 litres meet all your needs for storage, mixing and dosing.

We have a wide range of tanks and containers to use as watertanks or serve various other purposes. They may be open, closed, cylindrical, rectangular and with flat or conical bottoms. Our containers are manufactured from unpigmented polyethylene as standard, which means you can see the level of content through the material from the outside.

CPX containers and tanks are mainly manufactured from recyclable polyethylene. Uses include storage, mixing and dosage, and they have a high tolerance of chemicals. View the durability list for further information. We supply water, ventilation and drainage companies as well as the processing, pharma, food and chemical industries.

We assemble connections and accessories completely according to your specific wishes. Most of our containers feature a load-bearing top for possible mounting of pumps or agitators. All containers are delivered with a separate lid and some are also equipped with handles as standard.

Read more +

Containers and tanks in a single piece

We manufacture our containers and tanks in a single piece, completely without joins or tension. For you as a customer, this means the number of weak points is minimised. And since there are no joins, they are easy to clean.

Durable and Chemical-Resistant Tanks

CPX tanks are primarily manufactured from recyclable polyethylene with high chemical resistance. They are used in water and sewage (WSS) systems, HVAC, process, pharmaceutical, food, and chemical industries. Many of our tanks feature a load-bearing top for mounting pumps or agitators. All tanks come with a separate lid, and some models have handles for easy handling.

Thanks to polyethylene’s chemical resistance, our tanks can store acids, bases, and other aggressive liquids without risk of damage or degradation. See our chemical resistance list for more information.

Food-Approved and Certified Containers and Tanks

To ensure that our products meet high standards of quality and safety, we have tested two of the polyethylene materials used in many of our tanks. Both materials are food-approved in accordance with the EU standard EN 1935/2004, confirming that they are safe for contact with food.

For applications where the tanks come into contact with drinking water, a specific approval is required. A selection of our tanks is therefore manufactured from a material with WRAS certification (Water Regulations Advisory Scheme), confirming compliance with UK requirements for materials in contact with drinking water.

Information regarding food and drinking water approvals can be found under the specifications for each product.

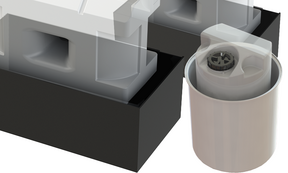

Safety casing

In order to increase the level of safety and meet more stringent requirements from the authorities, we offer safety casing for all our cylindrical closed containers and tanks. Safety casing protects not only against external impact but also against possible leaks where external equipment is connected. When safety casing is used, we recommend that all connections are made at the top of the container or tank.

Adapt your tank using our online tool

Our configuration tool is there for you to explore the various options suitable for your tank at your leisure. Having an account with us means you can:

• Easily adapt your tank with suitable connections and other accessories

• View your tank in 3D so you can see exactly what it will look like

• Save your configured products and continue later

• Download drawings

• View list prices for the customised tank and send a quote request

CPX Silos and tanks 200 – 10000 litres, with conical bottoms

CPX Silos are generally intended for dry products and CPX Storage tanks with conical bottoms for fluids. CPX rectangular containers with conical bottoms feature an optimised outlet to enable complete emptying of slow-flowing products such as mayonnaise, mustard, etc.

CPX Silos have a patented design that enables mass flow, facilitating emptying of the container. Maintaining an even mixture of different substances in a product where all particles have special properties is a must for many companies. Examples of this include ingredients in muesli, spice mixes, coffee and distribution of the raw materials in other products. The unique design of CPX silos ensures you maintain the "first-in-first-out" effect while simultaneously limiting the risk of common problems with separation.

We install connections, piping and other special adaptations on all these products. The finished tank is then ready for installation immediately after transportation.

CPX silos and tanks with conical bottoms are made of the same recyclable materials as our other containers and tanks, have no joins and are thus easy to clean.